Humane smolt stunner helps hatcheries target new markets

05 November 2021

Ace Aquatec’s humane smolt stunner can help the aquaculture sector further reduce its carbon footprint by converting waste into a natural, healthy and safe ingredient for pet food products and fish oils.

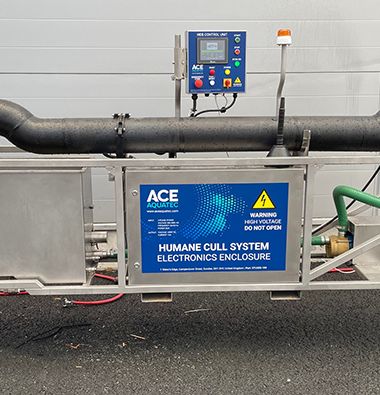

Using Ace Aquatec’s award-winning in-water Humane Stunner Universal (A-HSU®) technology, the Humane Culling System (A-HCS®) stuns smolt and juveniles without using chemicals, thus transforming a costly by-product into a sustainable fish source. It has applications for salmon broodstock and across fishery by-catches.

Fish due to be culled for quality reasons are typically treated with a chemical anaesthesia, rendering them unsuitable for consumption. They are then incinerated and end up either in landfill or in ensilage bins. By removing the need for chemicals, the smolt stunner provides a more ethical way of disposing of excess smolts at hatchery facilities, as well as producing an omega rich protein that can be harnessed for new revenue streams.

Demand for premium pet food has soared since the pandemic as pet owners choose healthier diets for their companion animals. Salmon offers a more sustainable source of protein for pet food than the wild fish that is traditionally exploited for this market and, with Ace Aquatec’s pioneering technology, is now a viable alternative. Meanwhile, the health benefits of omega 3 fatty acids, present in fish oil, are well documented and this market is tipped for significant growth, with increasing demand among the growing 65-plus demographic. The global fish oil market size was valued at $1,905.77m (around £1,379m) in 2019, and is estimated to reach $2,844.12m (£2,059m) by 2027.

Ace Aquatec adapted its humane electric stunner with a cull rather than stun setting for smolts. Juvenile fish are pumped into the entrance chute of the stunner, from where they fall directly into the water of the stun tube. The electric field in this water ensures that the fish lose consciousness immediately and never recover. The water is pumped at a rate for transporting the fish to the final dewatering grid over a period of about 40 seconds. The fish then fall into a harvest tub while the water is recirculated by an integrated water pump. Ice can be used in the harvest tub in order to preserve the fish.

Trials have shown that up to one tonne of smolts can be processed per hour, with 100 per cent stun/kill rates. The amount of waste from average hatchery facilities is between five and eight per cent of total production, but with Ace Aquatec’s smolt stunner enabling culled fish to enter the pet food chain, waste can be reduced to under one per cent of production.

Currently, Scotland produces approximately 55 million smolts a year; with five per cent (excluding natural mortality) culled at an average cull weight of 35g, that is 105 tonnes of fish waste annually. Farmers want to see their fish go to use, rather than going to waste, and Ace Aquatec’s self-contained, transportable smolt stunner offers an opportunity to reduce waste across their smolt grow out.

Jarl van den Berg, General Manager of Hendrix Genetics in Scotland, a leading salmon smolt production and breeding company, partnered with Ace Aquatec and New Zealand King Salmon in the development of the smolt stunner.

‘This is the best solution in the market in terms of animal welfare standards and environmental impact,’ he said.

‘The stunner will set a new sustainable standard for the rest of the industry to follow as it has improved our environmental footprint and more importantly allowed us to use the fish for value-added purposes”

The Ace Aquatec smolt stunner is now being rolled out worldwide.